Testing & simulation

Switch cabinets with which your products/machines can be simulated or tested.

We manufacture customised switch cabinets for you.

Reproduce, test, improve

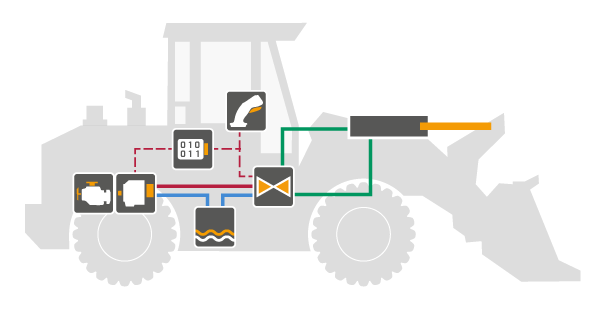

By setting up a test cabinet, hardware such as joysticks, displays, sensors, motors or complete machines can be simulated. Thus “components” can be used without having them on site. Using plug connections, power supply, inputs and outputs, and CAN communication between different hardware can be connected and checked quickly.

With this environment, it is possible to test products and code before they are delivered to the customer. This ensures consistent and high quality.

We help with the electrification of your working machine!

We help with the electrification of your working machine!